We use cookies to make your experience better. To comply with the new e-Privacy directive, we need to ask for your consent to set the cookies. Learn more.

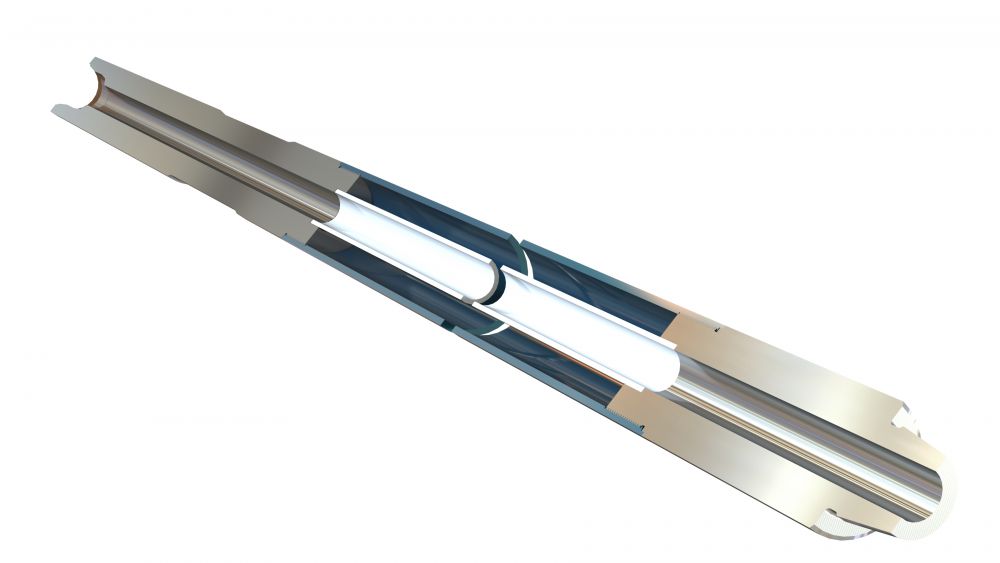

Drill Collars

Reel Power ME's Patented Shearable Drill Collars are designed to shear in commercially available Offshore Blow Out Preventers (BOP). Conventional drill collars have large cross-sectional areas for the weight and cannot be sheared in all BOPs, creating a section within the drill string that cannot be sheared. Drill Collars are 20 % heavier than traditional Collars. This reduces the number of drill collars required in the drill string. They provide a greater concentration of the weight on the bit. The Reel Power ME Drill Collar replaces the steel with heavy, softer lead to allow shearing by conventional BOP shear rams.

The Reel Power ME Patented Shearable Drill Collar improve environmental responsibility by providing another component that can be sheared within the drill string. The lead filled drill collar is softer than steel in traditional drill collars reducing the force and pressure required to shear in an emergency condition. The drill collar has been successfully tested in two (2) of the major offshore manufacturers of conventional offshore Blow Out Preventers.

The lower portion of the drill string with currently available, conventional steel drill collars is, typically, unshearable. In subsea operations, the drill collars are run through the shear rams in the BOP stack, immediately after drilling into the high pressure producing formation. This creates a window where the components in the drill string cannot be sheared. The Reel Power ME Patented Shearable Drill Collar reduces this risk.

Further, due to the manufacturing processes the concentricity is reduced and the harmonics are minimized. These factors may reduce the vibration allowing for better penetration rates, longer bit life and less wear on all downhole string components. In addition, the increased weight (20-25% greater weight) may reduce the number of drill collars required and provides benefit during the spud process. While drilling horizontal wells the added weight in the vertical section may assist in a greater reach or longer laterals, while using in the vertical section.

These Drill Collars have been designed to Transocean approved specifications and allow the box and pin couplings to be replaced when needed.

| Product Brochure |  |

|---|

Offshore Drilling