We use cookies to make your experience better. To comply with the new e-Privacy directive, we need to ask for your consent to set the cookies. Learn more.

Sheaves

Reel Power ME umbilical sheaves meet or exceed API 16D stringent installation requirements. API requires the sheave to be rated (SWL) for two (2) times the calculated force required to overcome the maximum braking capacity and motor torque output. The sheave assemblies are to be tested to 1.5 times the SWL.

Reel Power ME Umbilical sheaves meet or exceed API 16D stringent installation requirements. API requires the sheave to be rated (SWL) for two (2) times the calculated force required to overcome the maximum braking capacity and motor torque output. The sheave assemblies are to be tested to 1.5 times the SWL. Do Your Sheaves Meet API-16D?

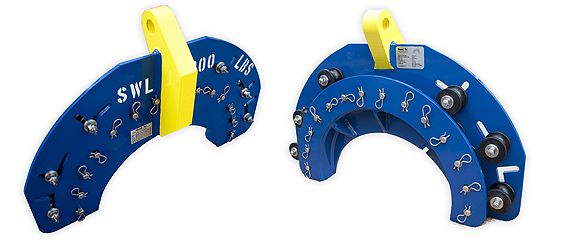

The sheaves are designed to ensure the bend radius of the umbilical / hose is not exceeded during deployment and retrieval. Sheaves are fitted with material retainer rollers that assure that the umbilical will always stay in the sheave. All surfaces that may contact the material are smooth and freely turn to help protect the umbilical.

Standard sheaves for BOP reels accept up to 2” diameter material with specifically designed to adhere to the minimum bend radius of the umbilical. Both single wheel and multi-roller sheaves are available. The top sheave is typically fitted with stainless steel swivel, while bottom sheaves may be provided with counter-weights to set a service loop within the system.

IWOCS and BOP Pod multi-tube umbilical hoses are available for over 5” diameter umbilicals.

We have designed and built a variety of sheaves including double sheaves with directional swivel capability to allow the umbilicals or hoses for two separate riser systems to be deployed and retrieved from one location without having to use valuable deck space for duplicate equipment.

Telescoping arm sheave may be provided to bring the umbilical further out over the moon pool. Load cell mounted sheaves may also be provided for direct tension feedback and control of your umbilical reels.

Sheaves can be provided with DNV or ABS certifications.Reel Power ME has produced umbilical reels for almost every deepwater application. Reel Power ME has developed many patented and patent pending features that Improve the Reliability and Safety of the umbilical deployment and Lower the Operating Costs of the Drilling Contractor.

Reel Power ME has produced umbilical reels for almost every deepwater application. Reel Power ME has developed many patented and patent pending features that Improve the Reliability and Safety of the umbilical deployment and Lower the Operating Costs of the Drilling Contractor.

Specification:

- Umbilical Sheaves (meet or exceed API 16D)

- Painted or Galvanized Carbon Steel with SS fasteners

- Stainless Steel sheaves

- UHMW Roller or Wheel sheave material

- DNV and/or ABS certifications

- Swivel and counterweights available

- Articulating and extendable sheave assemblies

- Load Cell provides tension output to display and for control functions

- Umbilical Riser Clamps

- Spare Parts Kits

Common Uses:

- Deepwater BOP Systems

- Electric Umbilical

- Fiber Option Umbilical

- Hot Line Hose

- Hydraulic Control

- POD Hose

- Dual Gradient

- Intervention Workover System (IWOCS)

- Hydraulic Multifunction Umbilical (Pod Hose)

- Downline & Wireline Operation

- Riserless Intervention

- Coiled Tubing

- Trusted Partner – Reel Power OG has manufactured more Umbilical Reels than anyone in the World and designing sheaves for many years.

- Meets or exceeds API-16D for safer operation.

- Meets ABS and DNV standards.

- Widest variety of sheaves available.

- Automatic control features available.