We use cookies to make your experience better. To comply with the new e-Privacy directive, we need to ask for your consent to set the cookies. Learn more.

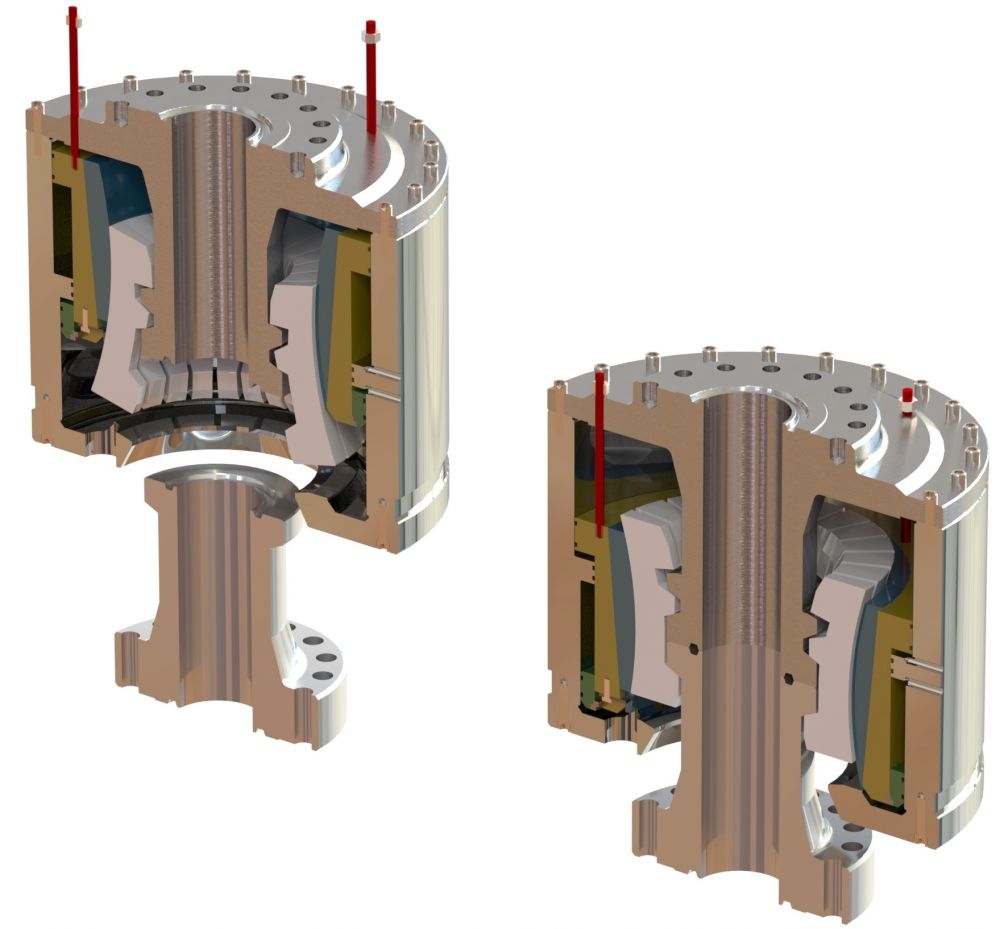

Loc-Torus Hydraulic Connectors

The Reel Power ME patented Loc-Torus Hydraulic Connector is a versatile replacement for standard torus style OEM connectors. The Reel Power ME patented “lock over center” design is ideal for multiple use applications where the need for greater reliability and functionality exist, especially in today’s cost conservative marketplace.

The Reel Power ME patented Loc-Torus Hydraulic Connector is a versatile replacement for standard torus style OEM connectors. The Reel Power ME patented “ lock over center” design is ideal for multiple use applications where the need for greater reliability and functionality exist, especially in today’s cost conservative marketplace.

Reel Power ME Loc-Torus hydraulic connector was designed with the operator in mind. Not only does it match the versatility of other Torus style connectors in a variety of applications, including subsea tree, Jumper, riser, tubing head, and flowline applications, but adds greater reliability by using our patented “ lock over-center” design.

The connector provides a sure connection at the wellhead, the “lock-over-center” design ensures the dogs are uniformly operated into the engaged and disengaged position, similar to the effect of a light switch. The connector was designed to fit standard subsea wellheads with 10K/15K psi pressure rating, standard wellhead hub or mandrel profiles, and for use in multiple aftermarket applications due to the ability to perform multiple locks/unlock actuations. A visual lock indicator rod gives position feedback via an ROV that the connector is locked. Flow zone components are designed for maximum erosion and corrosion life significantly reducing maintenance and replacement costs.

| Product Brochure |  |

|---|

Specification:

- Improved Environmental Safety

- Lock Over Center – Connector will not comeunlocked, even with vibration

- Indicator rod for visual lock-unlock confirmation

- Low Friction & Consistent Force Connection

- Interfaces can be Teflon coated rather than roughedup for conventional wedge locking

- Eliminates the need for secondary locking

- No Tendency to Self-Release under Pressure or Vibration

- Does Not Require Holding Hydraulic Pressure during operation

- Does Not Require Secondary Locking Mechanism

- Designed for 10 and 15K psi

- Preload Mechanically Set

- Can be adopted to older subsea wellhead and mandrel configurations and sizes

- Multiple Bore/Pressure combinations available

- H2S service capable

- Designed for maximum corrosion and erosion protection

- Lift eyes for easier handling

- Subsea Well Abandonment

- BOP Stack to Wellhead

- BOP to Riser Connection

- Lower Marine Riser Package (LMRP) to Lower BOP Stack

- Dry Tree Connector

- Completion Trees to Wellhead

- Tool/ Testing applications

- Lock Over Center – Connector will not comeunlocked, even with vibration

- Does Not Require Holding Hydraulic Pressure or Secondary Locking Mechanism during operation

- Designed for maximum corrosion and erosion protection