We use cookies to make your experience better. To comply with the new e-Privacy directive, we need to ask for your consent to set the cookies. Learn more.

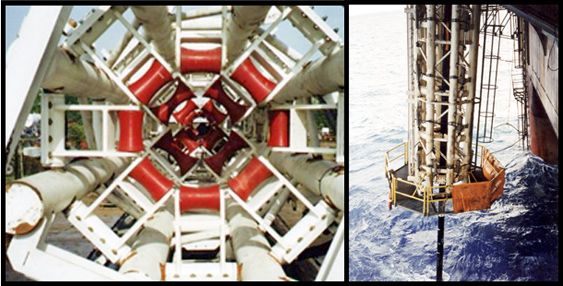

J-Lay Towers

Reel Power ME has designed and built Gimbaled J-Lay Towers with highly automated pipe welding systems that allow offshore pipelines to be laid safely in deepwater. One J-Lay Tower for OSI/Petrobras had a 58 ft. travel and another for Stolt had an 85 ft. travel with dual work stations making it equivalent to a quadruple joint lay system.

Reel Power ME has designed and built Gimbaled J-Lay Towers with highly automated pipe welding systems that allow offshore pipelines to be laid safely in deepwater. One J-Lay Tower for OSI/Petrobras had a 58 ft. travel and another for Stolt had an 85 ft. travel with dual work stations making it equivalent to a quadruple joint lay system. They contain sophisticated pipe laying controls monitoring the position as well as the vertical and horizontal force components of the pipeline exiting the stinger. The stinger assembly controls the bend radius of the pipeline leaving the vessel. The J-Lay Towers land on the pipe-lay vessel and provides a platform enabling the pipeline workers to weld, test and coat the pipeline in the vertical tower. The pipeline is then fed vertically down to rest on the ocean floor in a J-Lay fashion. Normal S-Lay or horizontal pipe lay methods exert very high stresses on the pipeline during deepwater lays primarily due to the pipelines own weight when the pipeline is fed off the pipe-lay stinger in a near horizontal position. The Gimbaled J-Lay feature allows the pipeline to be constructed in the vertical position and laid along the desired path even while the pipe lay vessel positions itself favorably into the wind, currents and waves. The Gimbaling capability also allows the pipe-lay vessel to rotate 180º to facilitate easy handoff of the SCR for installation on the receiving Platform.

Tower gimbals up to 15º from vertical

1,250,000 lb. Lifting capacity

Self-contained adaptable to various vessels

Sophisticated controls

Highly automated pipe welding system

Deepwater pipeline construction

Deepwater pipeline repair