We use cookies to make your experience better. To comply with the new e-Privacy directive, we need to ask for your consent to set the cookies. Learn more.

Coiled Tubing

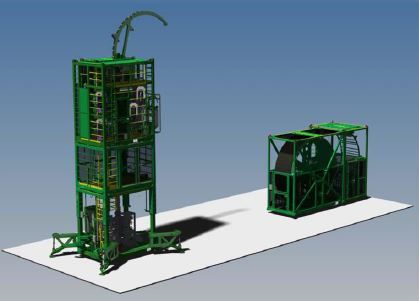

Current coiled tubing winch and coiled tubing deployment units use a heavy winch to handle and store the tubing. The coiled tubing is deployed to a tower sheave then to a straight injector and into the well. Reel Power ME patented unit includes a curved Catahead injector to handle the load.

Current coiled tubing winch and coiled tubing deployment units use a heavy winch to handle and store the tubing. The coiled tubing is deployed to a tower sheave then to a straight injector and into the well. Reel Power ME patented unit includes a curved Catahead injector to handle the load. The design saves footprint and can be placed near the moonpool or over the railing. The compact assembly requires no tower sheave. The tubing is wound onto the reel under normal tension.

Reel Power OG Coiled Tubing Handler Specifications

- Designed for 2” Coiled Tubing – Catahead chains can be replaced on-board to handle other CT sizes (2 3/8” size available).

- Designed for up to 80,000 lbs of CT tension (120,000 lbs available).

- Catahead is retractable for compact transport, then extendable for longer reach overboard.

- Reelpower OG's Patented Failsafe Parking & Emergency Brake included.

- Hydraulic or electric driven option.

- Local and remote controls available.

- Single or tandem configurations.

- Active Heave Compensation option.

- Operator control stand option.

- Compliant with DNV 2.7-3 option.

- Weight, Length Count and Speed readouts available.

- Coiled Tubing Deployment

- Offshore Well Intervention

- Jetting

- Chemical Treatment

Lower Your Operating Costs, Improve Reliability & Improve Safety

- Reel Power OG Patented Catahead system provides the lifting, not a traditional winch & injector .

- The Catahead replaces the sheave assembly and is mounted on the levelwind .

- Catahead tension capability of 80,000 lbs .

- Compact, integrated solution lowers deployment costs.

- Extends the tubing life compared to an offshore over sheave system.

- 20-30% Total Package Weight Savings – Smaller On-board & Transport Footprint .

- Greater Flexibility & Versatility with unit placement – can be placed at the moonpool or over the side .

- Safer Operation with redundant coiled tubing braking systems.